Aeration System

Surface AERATION SYSTEMS

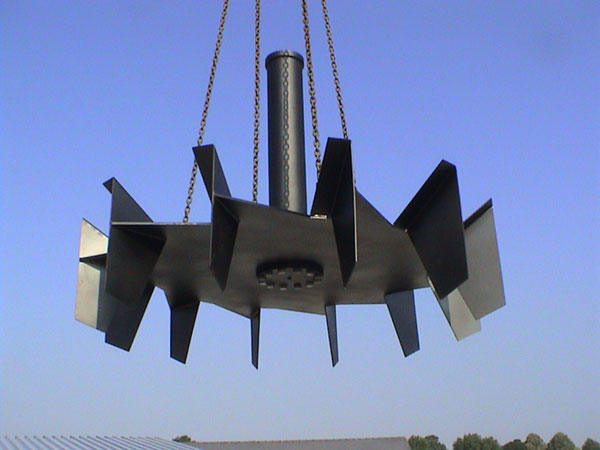

Surface aerators push water from under the water's surface up into the air, then the droplets fall back into the water, mixing in oxygen. The jets of water break the surface with varying degrees of force. There are many types of surface aeration devices, including floating aerators.

Surface aerators are available in both floating and fixed execution. Each of these aerators exists in high speed direct drive or low speed with gearbox execution.

Surface aeration, especially the high-speed aerators, have a high efficiency in real activated sludge conditions due to their favourable alpha factor, it is used mostly for the biological process of water purification and plant aeration.

This aeration system extracts water from the basin volume and utilizes air-water contact to transfer oxygen by means of a water spray on the surface. This is the ideal Aeration system for ponds and lakes.

DIFFUSED AERATION SYSTEMS

Aeration forms a vital part of the wastewater treatment process, particularly the secondary treatment phase. It mixes wastewater with oxygen to allow aerobic bacteria to digest biosolid particles in the water. Aeration plays a particularly vital role in the activated sludge phase, during which bacteria feed on organic matter until flocs of matter and bacteria settle out and form sludge. The sludge recirculates, along with its bacteria, to enhance further breakdown of organic matter within the wastewater. Diffused wastewater aeration systems provide a crucial tool for this process. They pump small, less concentrated amounts of air into the liquid to provide a highly efficient aeration process.

HOW DOES A DIFFUSED AERATION SYSTEM WORK?

A diffused aeration system typically operates vertically. It sends

up concentrations of bubbles from near the floor of a wastewater

facility’s lagoon or tank. Typically, the system comprises onshore

blowers, pipes and diffusers. Compressed air pumps through pipes

and filters into the water through the diffusers, which create

tiny bubbles. The bubbles displace and mix the water and create a

spiral flow pattern, transferring oxygen into the water column as

they rise to help bacteria do their work. Usually, the diffusers

cover as much of the floor as possible while allowing some space

for technicians to walk and do maintenance. This full coverage

allows for an even distribution of oxygen. Plants can determine

the number of diffusers and blowers necessary by considering the

volume and type of sewage and the dimensions of the treatment

tank. Diffused aeration systems come in two main types — fine

bubble and coarse bubble. Fine bubble aerators provide enhanced

aeration and efficiency, while coarse bubble aerators excel at

mixing and increasing the level of dissolved oxygen. Each type of

bubble aerator has specific airflow requirements, so plant

operators must choose blowers and pipes accordingly.